This is our first update on the B-17 restoration. These updates will become more regular and frequent as the restoration progresses. In the near term, progress is slow. As you would expect, we did a lot of planning for the arrival of the aircraft. But some things we simply could not do until the aircraft was here. After we got the fuselage into the Scott Hangar, one of the first tasks to be completed was removing all the windows. That was a quick and satisfying job. Floorboards and the top and chin turrets were also removed.

View inside the B-17’s nose compartment with the windows removed. The light stand is in the hole where the chin turret was located.

A top priority now is building fixtures for the front and rear fuselage so we can split the fuselage at the production break behind the radio room. The two fuselage sections will be much easier to access and move around. Once the fuselage is split, we’ll get the paint stripped inside and out and then make a careful assessment of the condition.

Inside the waist section looking forward. The yellow light stand is in the radio room. The fuselage is designed to be separated at a production break just behind the wall or bulkhead separating the radio room from the waist compartment. The hole in the floor is where the ball turret was located.

Our restoration team has made good progress on identifying and tagging loose parts. They’ve also been opening access panels on both the fuselage and wings for inspection purposes. One engine support fixture has been completed and the engine installed for both display and future restoration work. A second engine fixture is in progress.

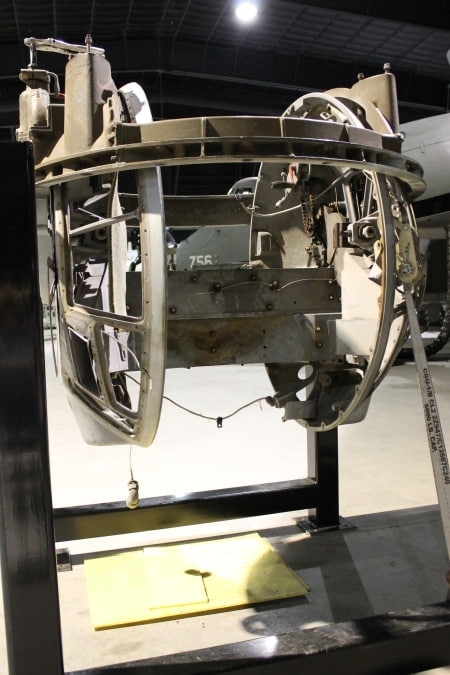

The ball turret has been mounted on a support fixture and restoration volunteers have been removing components for inspection, cleaning, and repair.